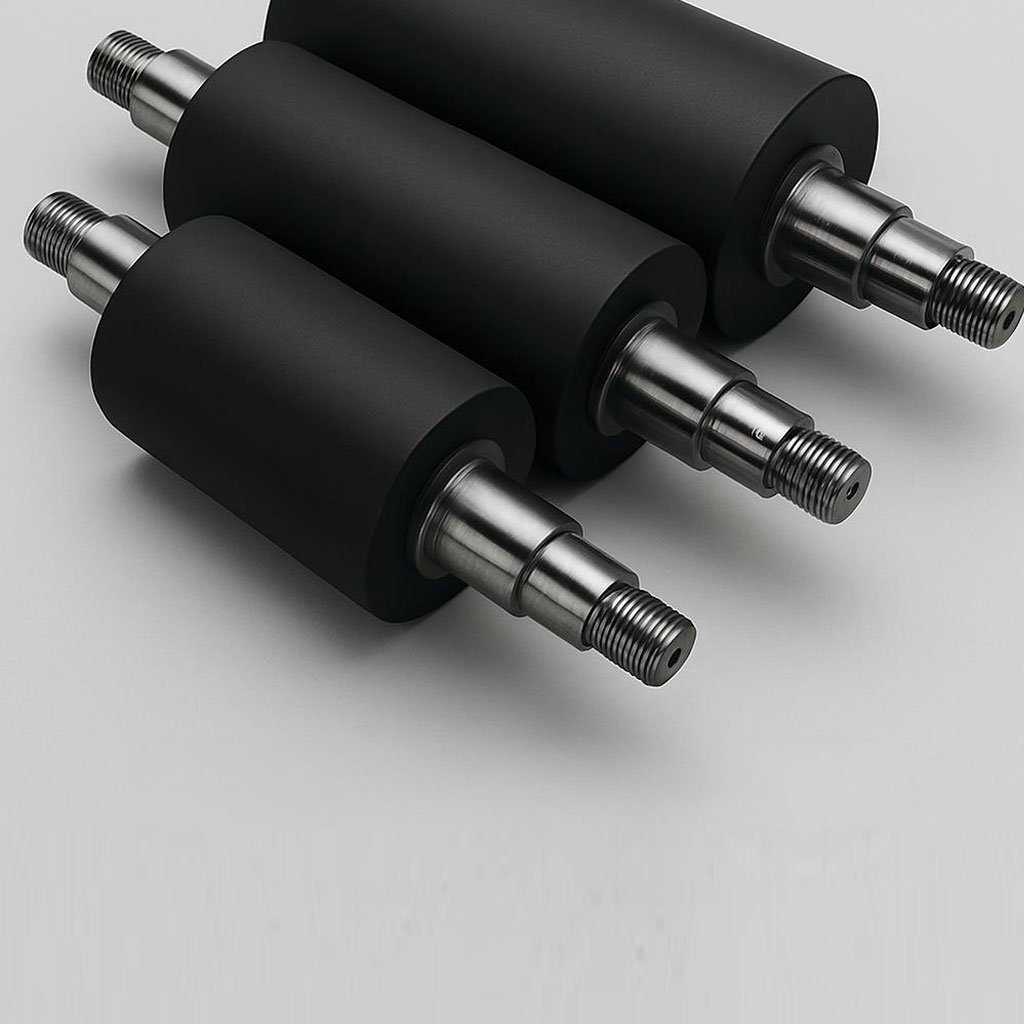

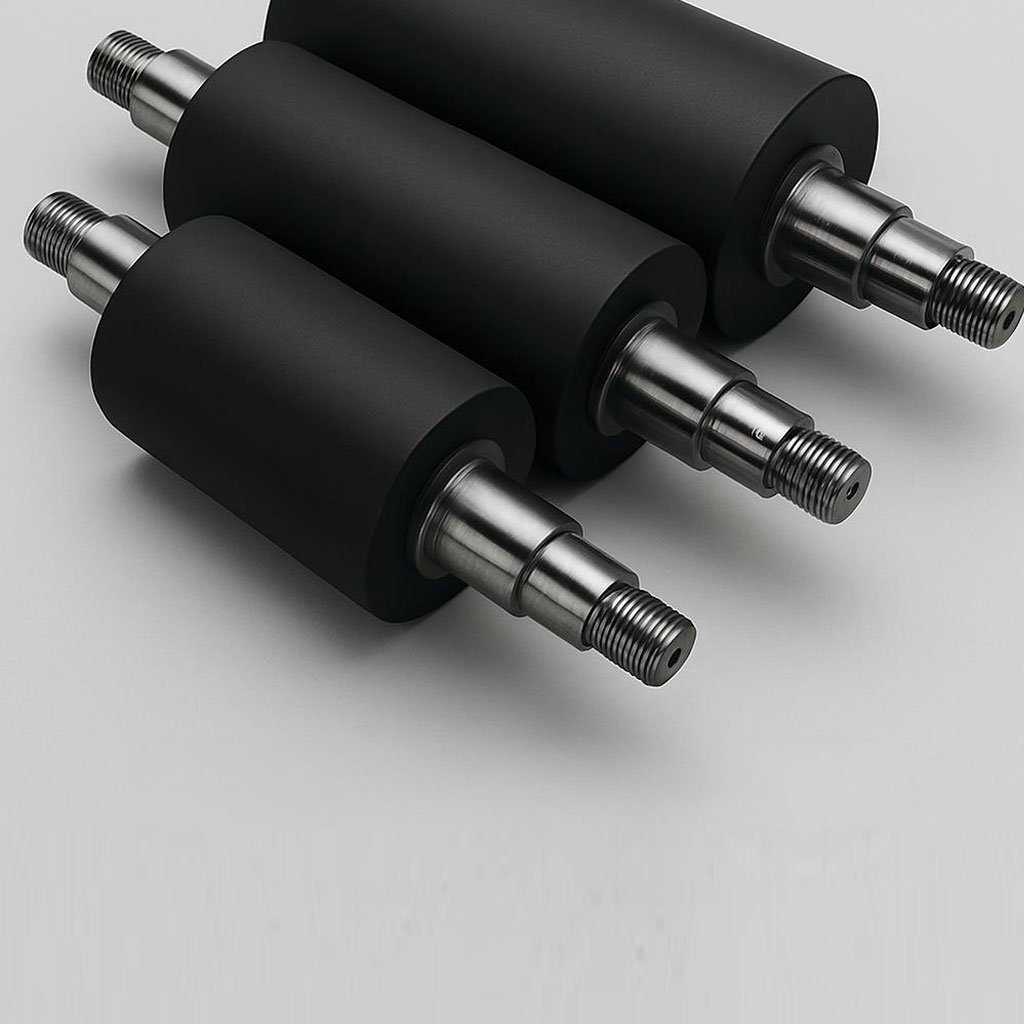

Rubber Mixing and Calendaring Rolls are precision-engineered rolls designed for use in rubber processing machinery, specifically for mixing, blending, and forming rubber compounds. Manufactured from high-quality forged steel or chilled cast iron, these rolls feature high surface hardness, excellent wear resistance, and superior thermal conductivity—ensuring efficient heat transfer and consistent processing.

Mixing rolls are used in two-roll mills or open mills, where they provide thorough and uniform blending of raw rubber, additives, and chemicals. Calendaring rolls, on the other hand, are used in calendaring machines to convert rubber compounds into thin sheets or coatings with precise thickness and surface finish.

All rolls are dynamically balanced and can be custom machined with smooth, grooved, or textured finishes based on specific process requirements.

Rubber Mixing and Calendaring Rolls are widely used in the rubber, plastic, and polymer processing industries. Applications include:

| Carbon | Silicon | Manganese | Nickle | Chromium | Molybdenum | Hardness | Tensile Strength | |

|---|---|---|---|---|---|---|---|---|

| Shell | 2.90-3.30 | 1.00-Max | 0.50-1.00 | 1.00-2.50 | 1.00-1.50 | 0.25 | 65-75 | 350-500 |

| Core | 3.10-3.50 | 1.50-Max | 0.60-0.90 | 0.40-1.00 | 0.25-0.50 | - | 30-40 | 350-500 |

| Shell | 3.20-3.50 | 1.00-Max | 0.50-0.70 | 1.00-3.50 | 1.20-1.80 | 0.25-0.50 | 75-85 | 350-500 |

| Core | 3.20-3.50 | 1.50-Max | 0.60-0.90 | > = 1.00 | 0.25-0.50 | - | 30-40 | 350-500 |